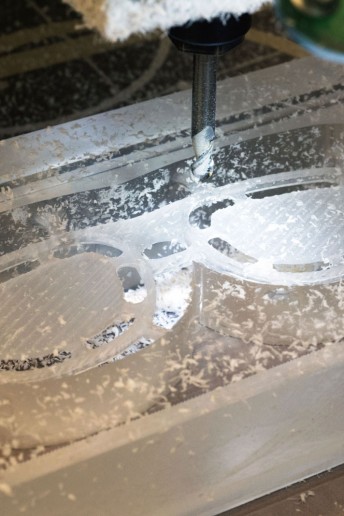

Laser cut, cnc milling on 4 axes, surface finishes and silicon molds

Laser cut

In our own laboratory in Milan, 1a100 provides laser cutting and engraving service on a “useful” size of 600 to 450 mm, on thickness (depending on materials) which start from a few tenths up to 10 mm of non-metallic materials, such as methacrylate, wood, plywood, textiles, leather, paper and cardboard.

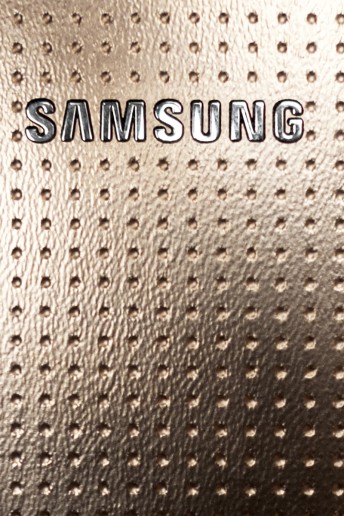

Finishings

We combine with the use of machines a wide range of possible surface finishes, ranging from painting with different techniques to polishing for perfect transparencies, by metallization in vacuum bell to metal layer® . With the latter one is the application even on standard plastic resins or rapid prototyping of a thin metal layer, on which it is then possible to make the classic galvanized finishes, until the chrome or gold plating. The layer deposited on the objects greatly increases the mechanical features and resistance to temperature compared to the starting material.

Clients often asks for special finishes for the most different requirements. With the experience gained over the years and through the great knowledge of materials, we can achieve astonishing results.

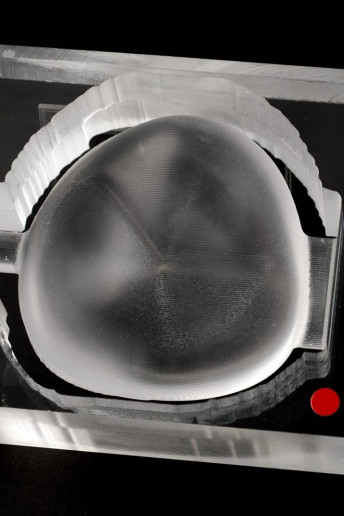

Silicone molds

Thanks to our know-how matured in years of activity, 1a100 can realize silicon molds with different typology and dimensions, useful for limited series of technical components in plastic, rubber or silicon. 1a100 can reach the target of reproducing anatomical parts and objects of various nature.